Reticle Stocker Optimization Project

Optimized reticle stocker management by cleaning raw data, automating pull prioritization, and delivering real-time, actionable reporting for Microchip Technology Inc.

Year

2023

Client

Internal Project / Microchip Technology Inc.

Role

Data Analyst / Process Enhancement Specialist

Project Overview

This project tackled a persistent bottleneck in reticle stocker management at a semiconductor facility. Raw warehouse data was filled with inaccuracies, including outdated records, misplaced headers, and stale utilization counts. These issues led to full stockers, wasted labor, and repeated manual rehousing.

My Approach

• Extracted and cleaned structured data using SQL and Excel.

• Standardized fields and removed redundant or misleading information.

• Engineered dynamic formulas to calculate inactivity and prioritize reticle extraction.

• Developed conditional formatting and pivot tables for fast, actionable reporting.

• Reduced congestion by establishing a pull priority system, leading to more accurate pull sheets and smoother operations.

Business Impact

• Decreased operational bottlenecks and manual handling.

• Improved decision-making for stocker management.

• Created a scalable workflow for ongoing inventory optimization.

Tools Used: Excel, SQL, Pivot Tables, Conditional Formatting

Figure 4: Reticle Risk Breakdown After Prioritization

Quick summary of how many reticles fell into each priority band after applying the stoplight method. Only 4 required urgent attention-down from a cluttered mess.

Figure 1A: Raw Data Before Cleaning and Transformation

Data with misaligned headers, redundant columns, and unnecessary timestamp details, hard to analyze and prone to errors.

Figure 2A: Data After Cleaning and Standardization

Cleaned up fields, aligned headers, and simplified dates. Ready for accurate analysis and reporting.

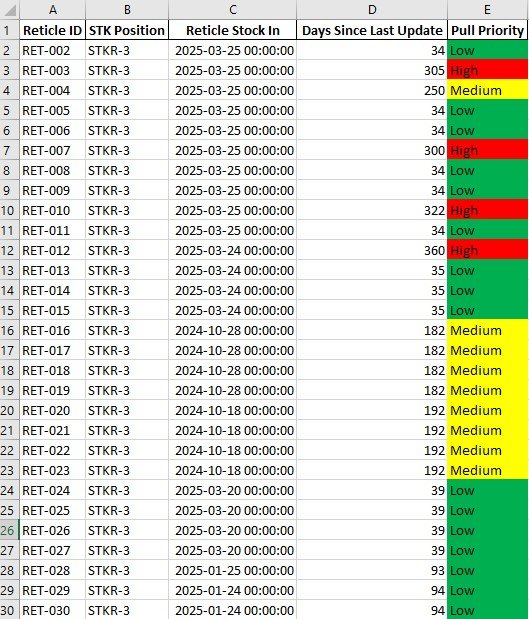

Figure 3B: Stoplight Pull Priority Table for Low Use Reticles

Conditional formatting highlights Stoplight color-coding (red = high, yellow = medium, green = low) instantly flags which pods need attention, letting the team prioritize maintenance at a glance.

Results & Business Impact

Key Outcomes

Reduced high-risk (red) reticles to just 4 out of 29-making urgent issues clear, not hidden.

Every stocker now operates in the “low utilization” range, eliminating congestion and wasted time.

Managers instantly see what needs action. No more bottlenecks, no more guesswork.

Figure 5: Stocker Utilization After Targeted Extraction

After fixes, all stockers moved into low utilization-no more congestion. Efficiency gains weren’t just theoretical; they show up in the numbers. This solution eliminated an average of 6-8 hours of manual tracking per week, freeing up a full workday each month for the operations team to focus on real problems, not just spreadsheets.

Wrap-Up:

Automated the workflow, killed the bottlenecks, and made stocker management a source of efficiency- not headaches.